LLS #1: Lenses and Lasers, A Necessary Connection

The unsung hero of the laser industry is the lens (slight hyperbole 😊). Today we can find a host of content on the internet about the pervasiveness of lasers. In fact, it would be safe to say that lasers have shaped our society as much as computers and cell phones. Without lasers, computer chips and cell phones could not be made in same size and power as we come to take for granted.

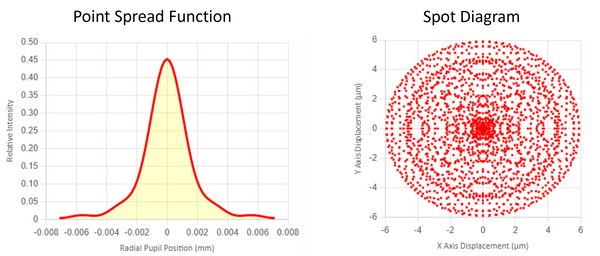

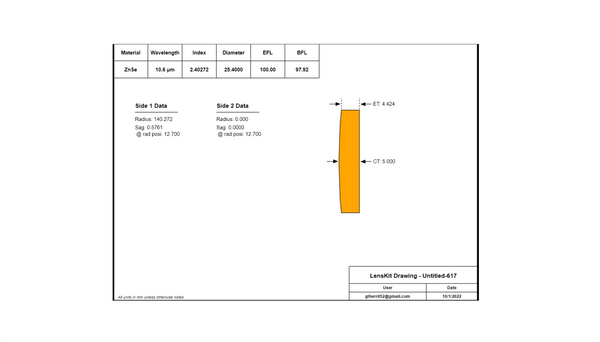

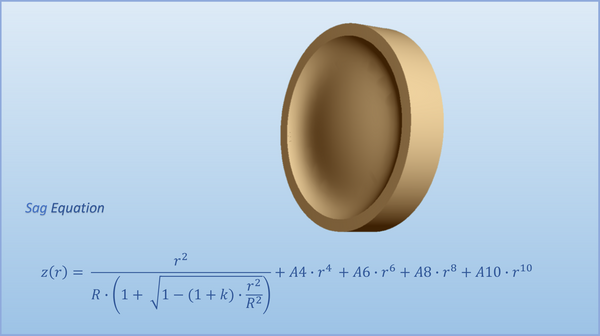

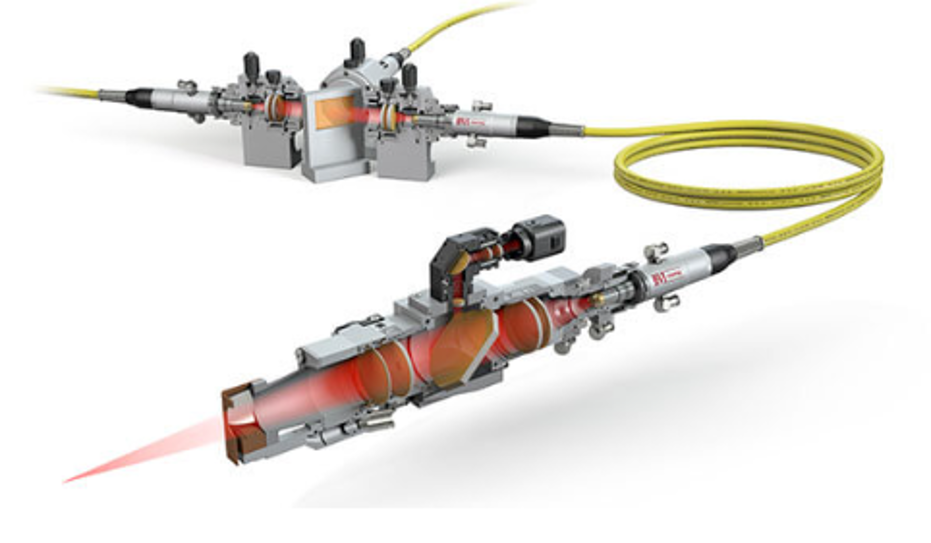

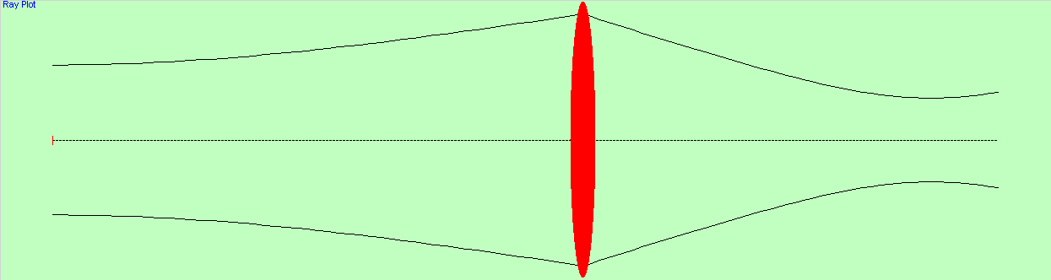

In the same vein, laser light cannot be harnessed without the use of mirrors and lenses. Lenses can be found in virtually all laser applications. They guide, shape, and focus the laser beam in ways that enable the laser beam to do work.

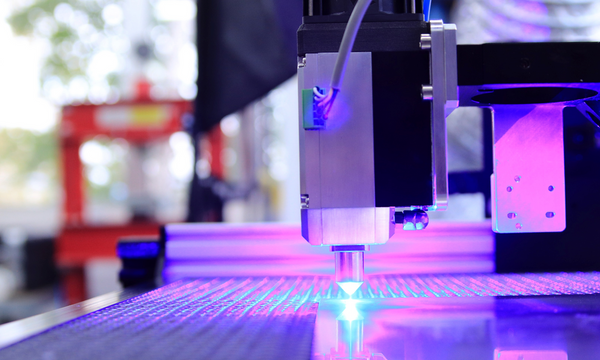

Lasers and lenses can be found in high tech applications like patterning of semiconductor chips on the nanometer scale, as well as in the low tech, but commonplace laser pointer.

https://www.asml.com/en/technology/lithography-principles

https://www.asml.com/en/technology/lithography-principles/light-and-lasers

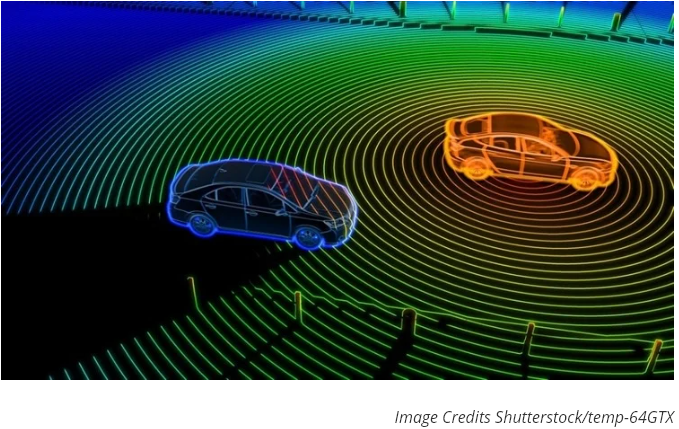

Lasers and lenses can be found in almost all aspects of daily life. Lasers welded the body parts of your car, they cut sheet metal for your refrigerator, they engraved many of your product labels bought at Walmart, and they helped you check out at the cash register. These are just a few of the many ways lasers touch our life every day. And, as self-driving cars become commonplace, we may well be trusting our lives to the robustness of this technology!

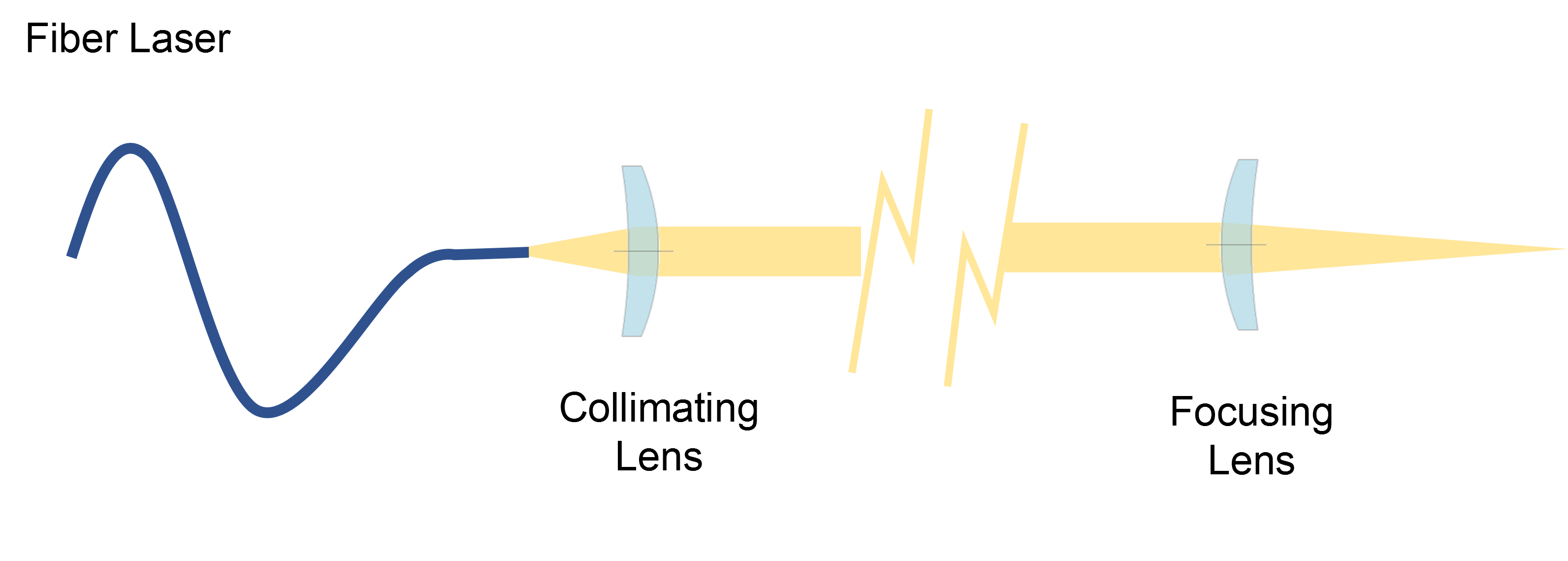

Lasers produce beams of various sizes and divergences. One of the misnomers of the technology is that laser beams are collimated. Without getting too picky about the terminology here, it is safe to say that every laser beam will eventually diverge or increase in diameter as it travels away from the laser. Because of this, lenses are needed to control the beam size. With that being said, we will use the term collimated laser beam through out these posts to refer to a laser beam with a minimum amount of divergence.

Up Next:

Visit https://www.lenskit.app to design and analyze laser lenses.